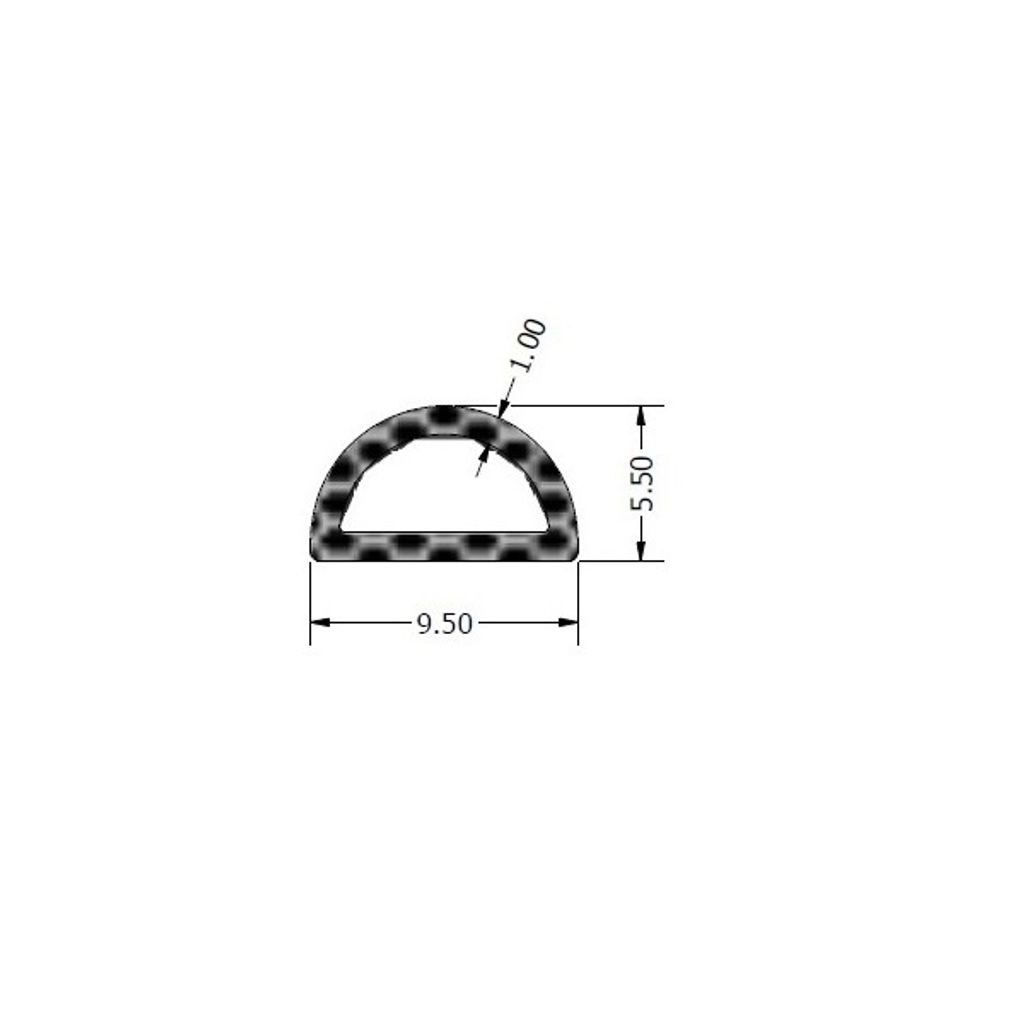

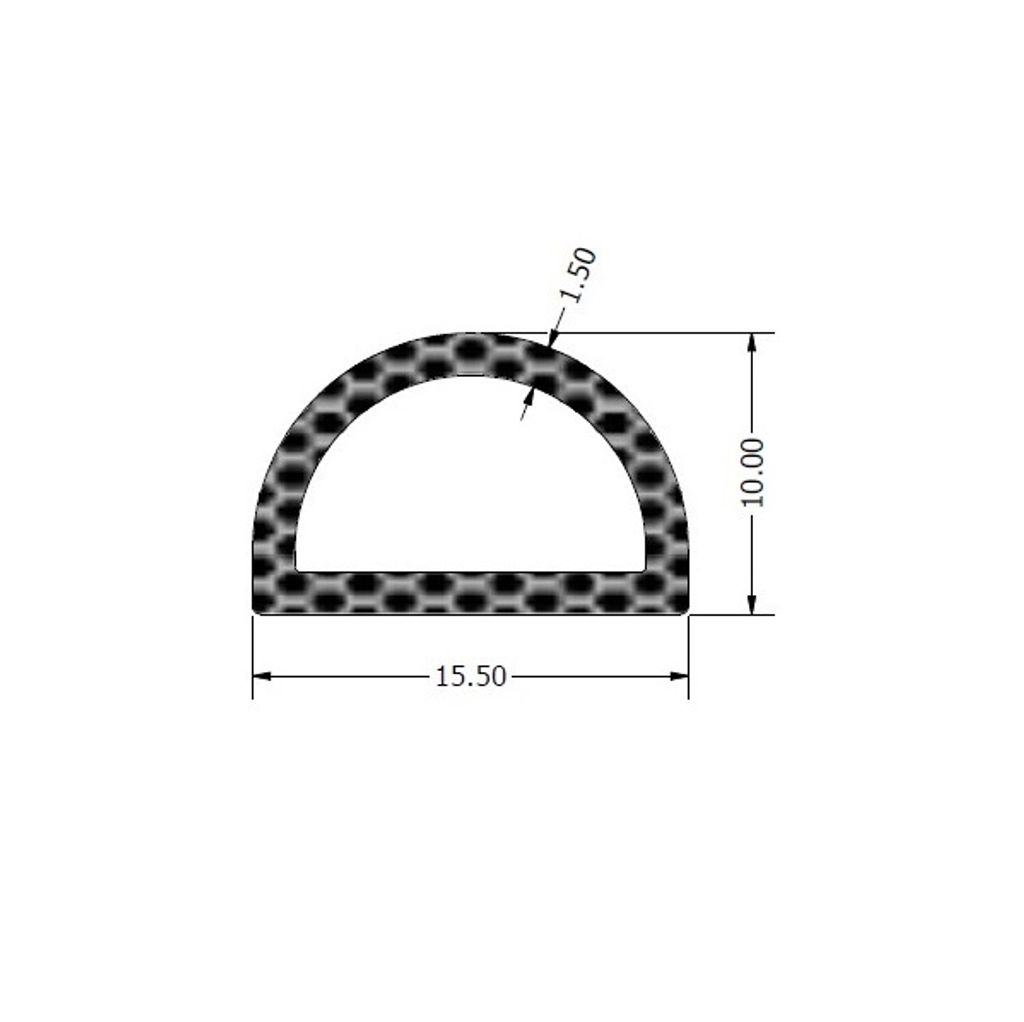

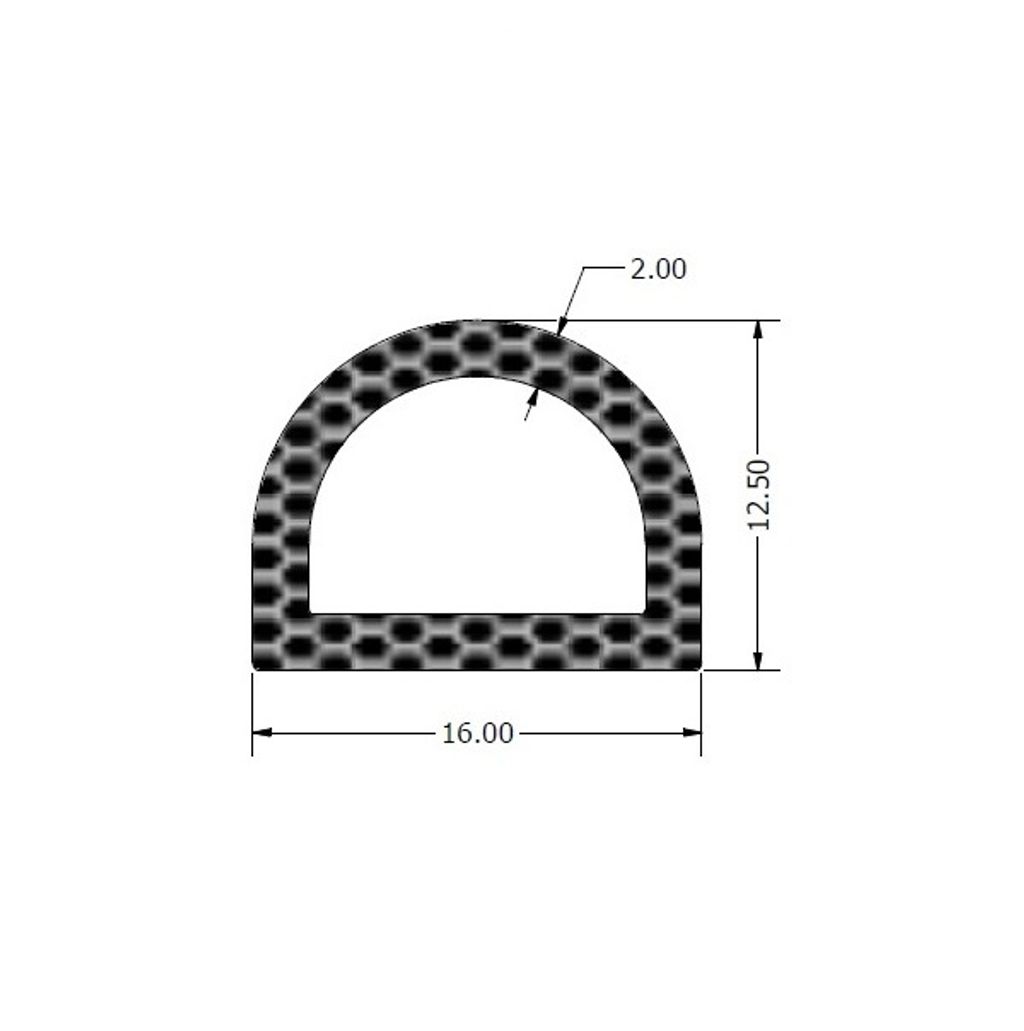

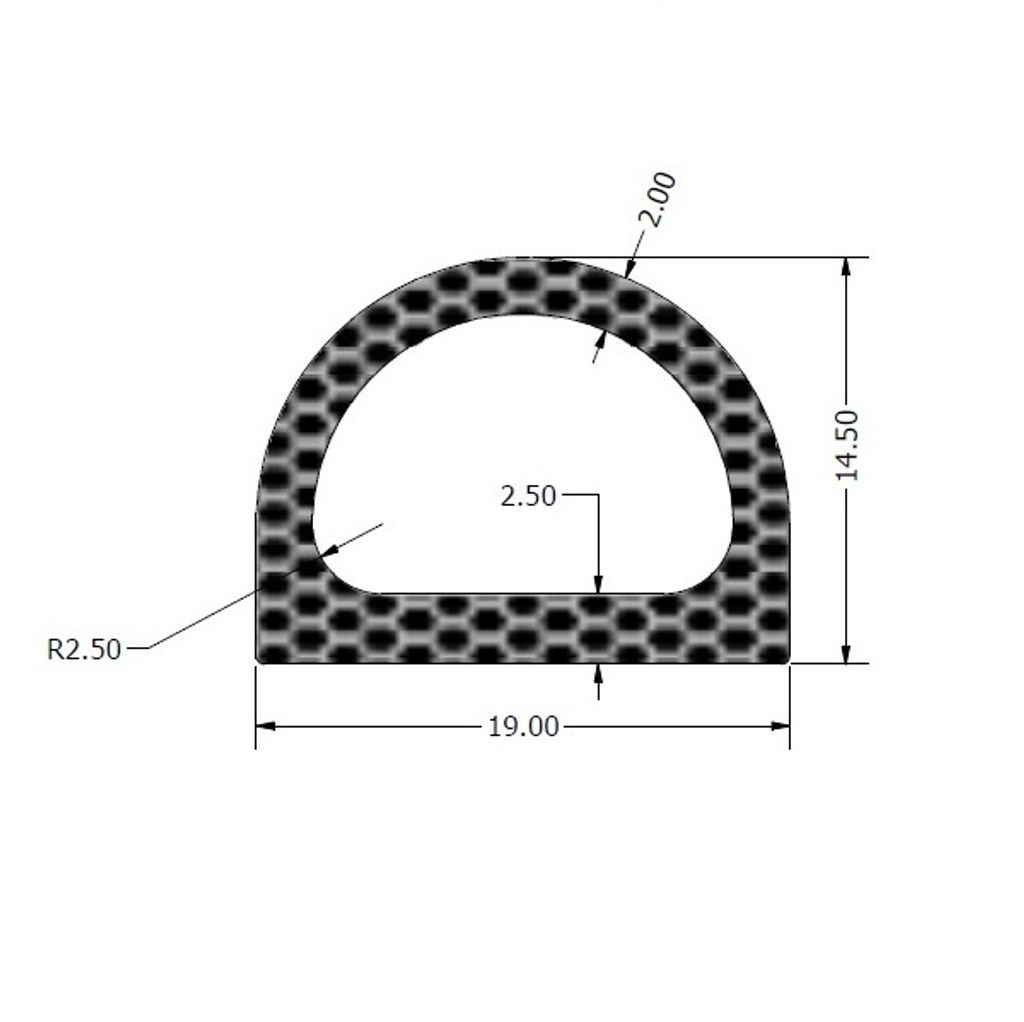

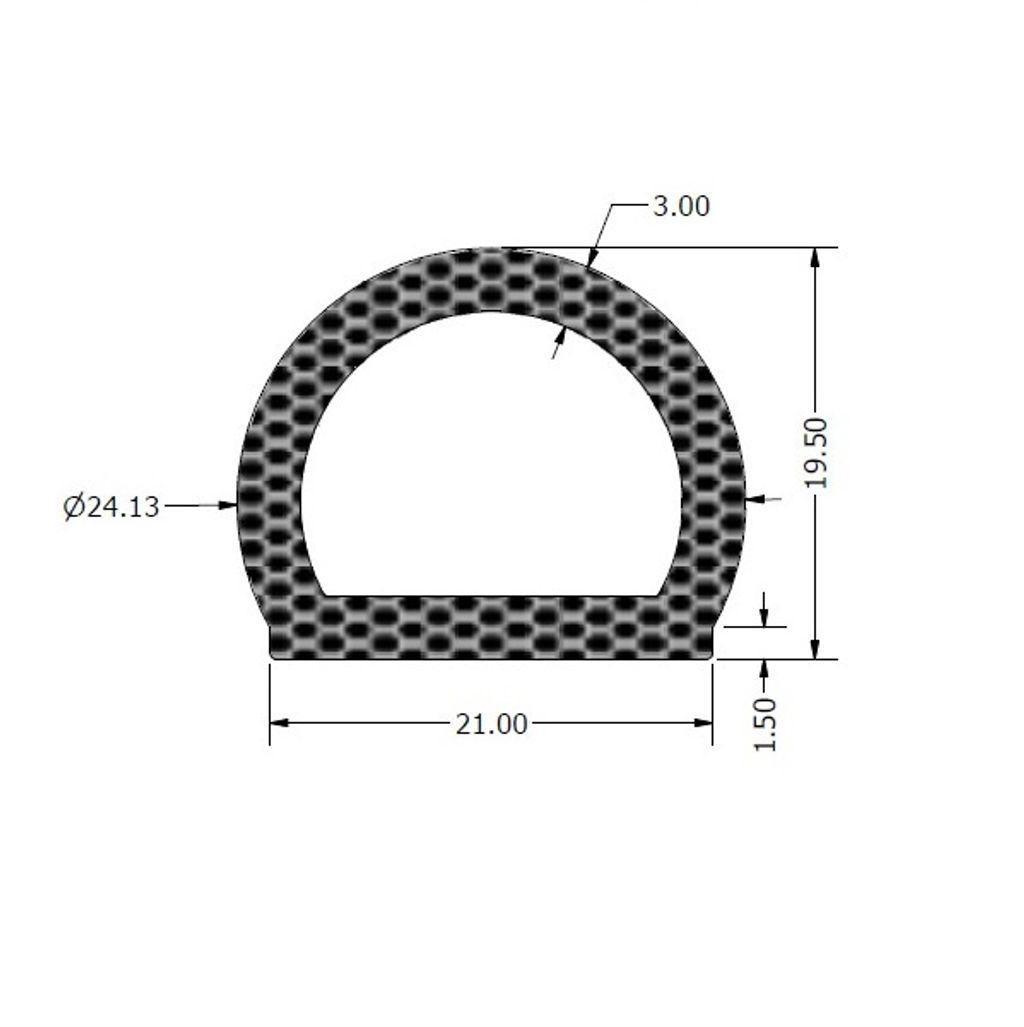

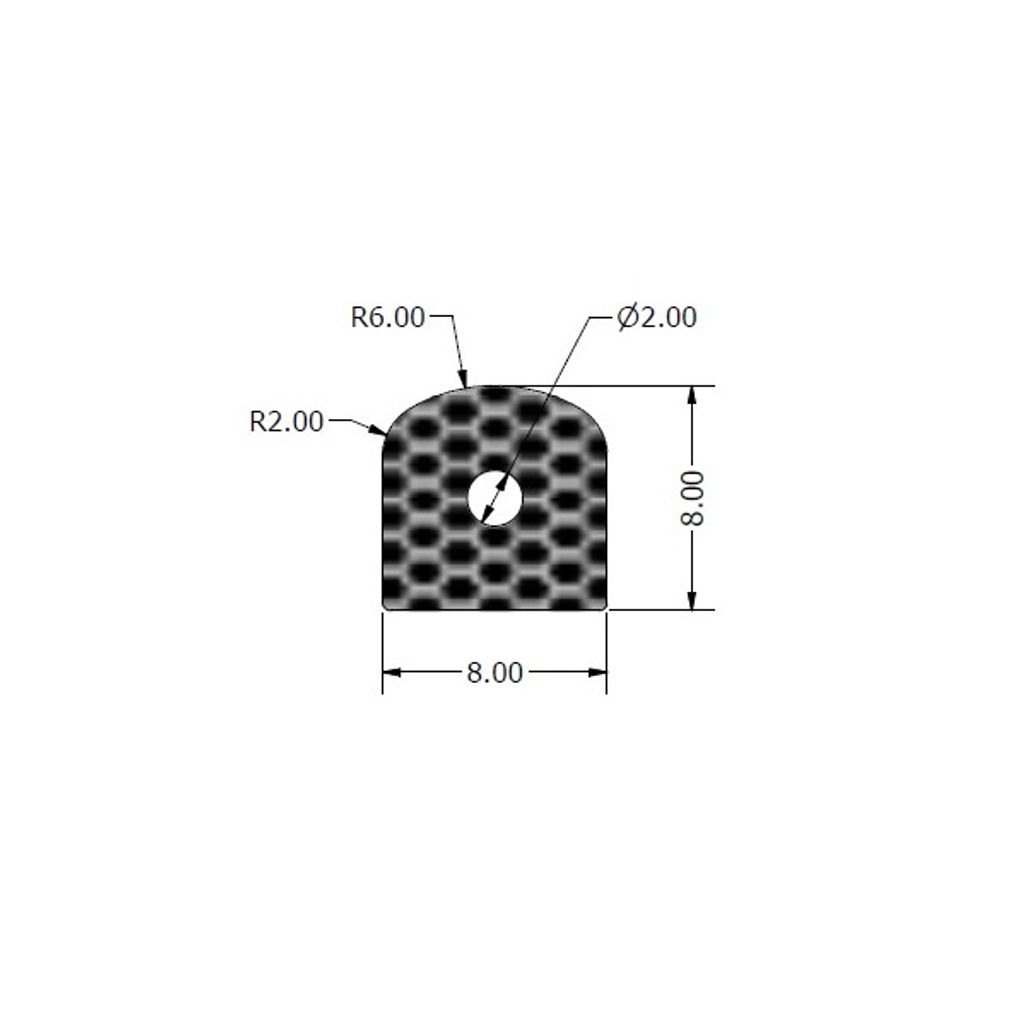

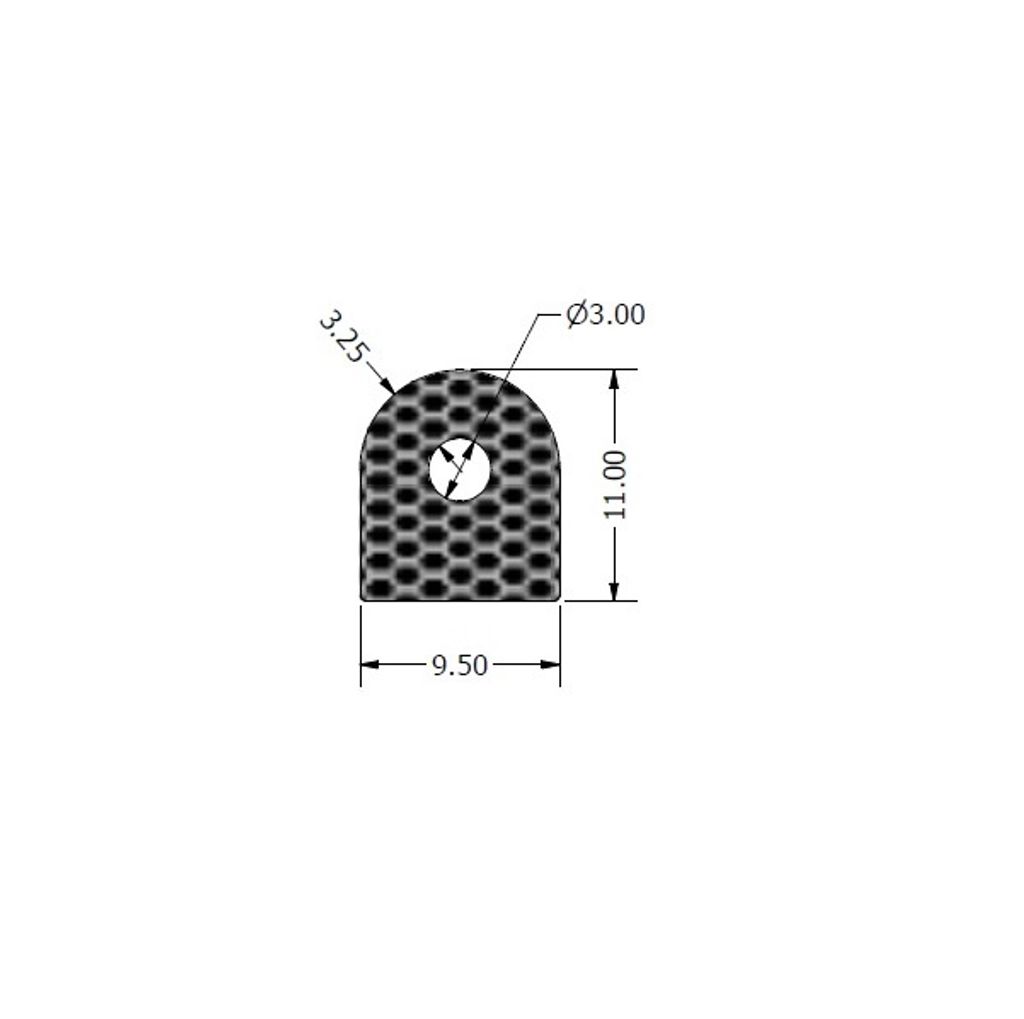

EPDM Rubber Sponge D Profile / D Sections Sponge Rubber Seals, Black, Made in Malaysia, price per meter length

If a customer orders 1m/pc x 5 pcs, we will provide 5m/pc uncut (cut to length or full length), subject to stock availability. Up to a maximum of 25m/roll

EPDM sponge (Medium Density Ethylene Propylene Diene Monomer) is a closed-cell sponge suitable for sealing applications.

The main properties of the EPDM "D" Sections are their excellent resistance to ozone, UV, and weathering and their general resistance to abrasion.

It is made from a high-quality closed-cell EPDM rubber with skin on all sides.

Specifications:-

1) Colour, Black

2) Density: Medium Density

3) Hardness: 40 SRIS

Its advantages also include

Excellent resistance to ozone

Excellent resistance to sunlight

Good low-temperature flexibility

Resistance to water and detergents

Resistance to mild acids and silicone oils

Disadvantages of EPDM rubber include

Poor resistance to petroleum oils and fuel

Poor resistance to mineral oils

Poor resistance to petroleum-based lubricants

CLEANING AND APPLICATION INSTRUCTIONS

Regardless of the bonding surface, it must be clean and free of surface contaminants such as oil, grease, mould release, and dirt.

Most bonding failures are due to improperly cleaned surfaces.

Before applying any adhesive, clean the surface with 50/50 isopropyl alcohol and water solution.